Printing of all types

Printing

Printing has evolved since that time With the development of modern technology tools such as graphics, which means the use of 3D printing and its exploitation in more modern and modern forms, in addition to color printers and others. We cannot do without it today, as it is important for all businesses and commercial projects, that most of the things that we use in our daily lives are included in the printing process. You gain beauty in the outward appearance of all goods, materials and even services.The quality of the printing and design and their distinctive shape, is what often makes you judge the product, whether you are convinced of buying it or not, and it is what makes you expect the quality of the product, and the design overlaps with printing to form the outer cover for the packaging of products and goods Even items such as pens, notebooks, etc.

Types of normal printing:

- uv-lak embossed printing: It is the oldest type used since the middle of the fifteenth century, and is based on the principle of inking letters or prominent shapes from wood or metal and then printing them on paper, using ceril plates, polymers and other materials, such as colored resins and thermoplastics. And that with placing it under strong pressure on the surface to be printed on and using molds to produce three-dimensional shapes

- Intaglio printing: It means using a mechanical engraver to engrave words, images, and symbols on a copper cylinder so that the cavities are filled with words and when pressed upon them, the expressions appear.

- Flat printing: It was invented by the German scientist Alois Steffelder and is based on the principle of lipid separation of water; As the acid separates from the ink, and when printed on the paper, it picks up the ink without the acid.

- Porous printing (UV): which requires a wooden frame that contains a silk mesh coated with a special type of paint, and another light-sensitive material, and is based on the principle of allowing light rays to pass through, which is a difficult method and requires special conditions.

Types of paper printing

Standards that enter into the paper industry, so we find a difference in paper weights, such as 75 grams paper, which is used for text and printing on a daily basis, and the 90 grams type is used for regular printing and pictures, and is suitable for both sides. As for the 150 and 200 grams type, its uses are often in Print accurate, vivid color and gradual color, there are different sizes of sheets and you must figure out the size that best suits your business.

The coating is an insulating and glossy layer, and it is used to print posters and pictures. This coating is an insulator that prevents ink from absorbing the ink and the appearance of spots, and shows the images correctly and very accurately.

Offset

It is most common for printing in high quality and quantities from medium to large. It is printed in basic colors, Pantone, or Mixing colors. The printing units are from one color to 8 colors, in addition to units of varnish, UV or Waterbase.

Digital printing

It has become famous in the recent period, and it is a printer, but in a large size and with more quality inks and it is characterized by high speed and the ability to print only one copy.

There are now many digital printers with binding units that carry out the process of stamping the magazine or book, and there is a cellophane and cutting machine in small sizes.

Among the most famous disadvantages: the damage of the inks from the sun and the high price of the print, especially for large quantities.

Printing by mail or ranch and printing on ready-made cards or envelopes in small sizes.

Embossed lettering

It is one of the oldest types of printing, and it uses ready-made letters of metal that are assembled letter by letter, and printing is done by pressing, and the advanced ones are made by cyrill.

Some types are automatic, mostly manual cylinders, and are famous for having a feel like a footprint.

Printing by Ciarel or Zinc and is printed on ready-made cards or envelopes in small sizes

Flexographic printing

Flexo printing is used for paperboard, kraft paper, corrugated paperboard, all plastic films and flexible packaging as well as aluminum rolls and stickers

Printing by Searell and printed on a roll of paper, sticker, or sheet, such as Corjetide

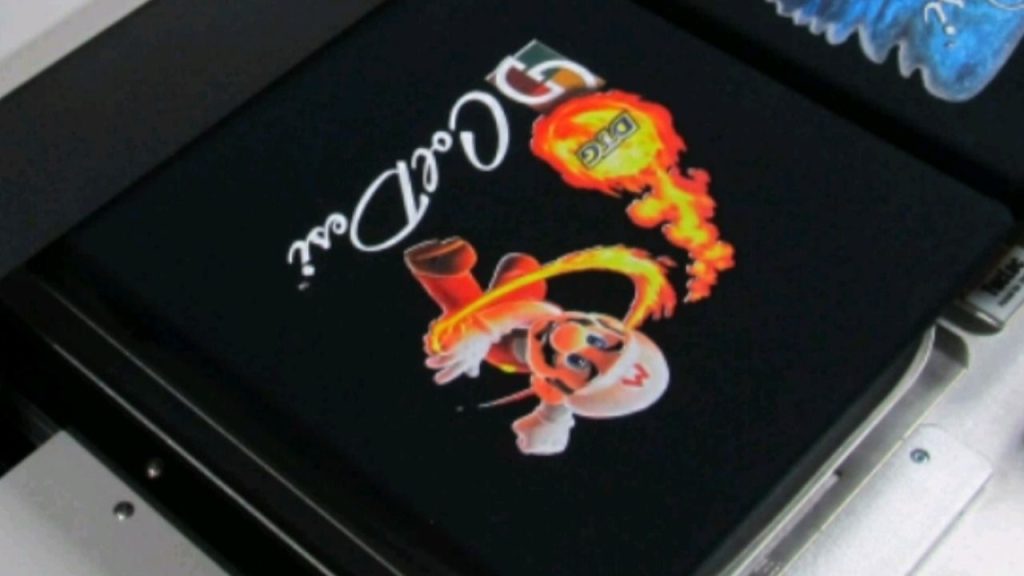

Silk screen printing

It is used to print on all flat and circular surfaces and on all materials that cannot be printed by well-known printing machines, offset, photocopy, laser…etc.

It is easy to use and low in costs, but one of its biggest drawbacks is networks, especially pictures.

Printing by silk-screened on any ready-made product, plastic or metal, fabrics – cups – pens – medals – shields – watches and T-shirts. It is also used to print Yuvi on the sheet.